In the realm of optical engineering, achieving precise beam focusing and collimation without introducing spherical aberration is a critical challenge. Bena Optics' Off-Axis Parabolic (OAP) Mirrors are designed to address this challenge head-on, providing unparalleled precision and flexibility in optical systems.

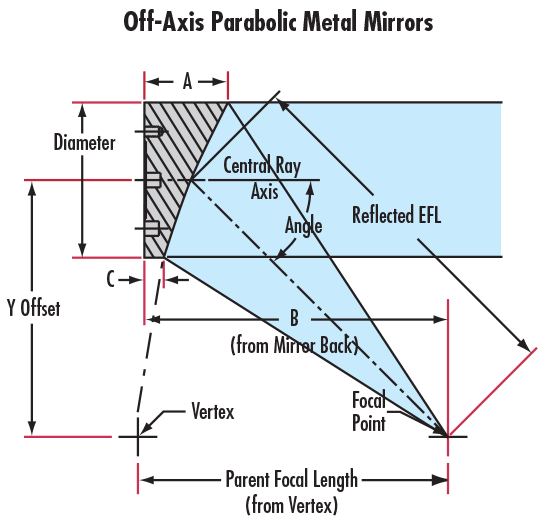

Off-Axis Parabolic Mirrors (OAP) are a segment of a larger parabolic mirror, offering a unique advantage over their centered counterparts. While both types of mirrors can focus collimated light to a point, OAP mirrors allow for greater interaction space around the focal point without disrupting the beam, as illustrated in Figure 2.

Figure 2: The schematic diagram of OAP shows how their unique shape allows the focal point of the mirror to be approached.

Focusing Collimated Light

When collimated light is incident on an OAP mirror, it converges to a single focal point. This capability is particularly useful in applications where maintaining beam integrity is crucial, such as in laser systems and optical instrumentation.

Variability in Design

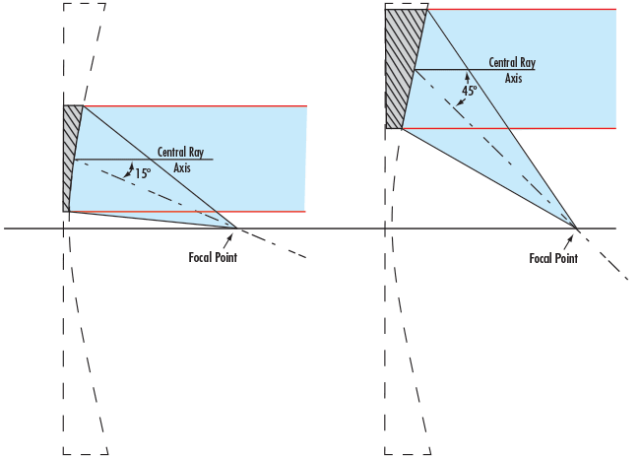

The angle between the focal point and the central ray axis varies depending on which portion of the parabolic shape the OAP mirror replicates. This variability is demonstrated in Figure 3, which models 15° and 45° OAP mirrors. It's essential to ensure that the incident beam remains parallel to the optical axis; any angular displacement can introduce comatic aberration, affecting the beam's quality.

Figure 3: Schematic diagrams of 15° and 45° off-axis parabolic (OAP) mirrors.

Diverse Coating Options

Bena Optics offers a range of coating options for OAP mirrors, tailored to meet the specific requirements of various optical applications. These coatings enhance the performance and longevity of the mirrors, ensuring they function optimally in different environments and spectral ranges.

Common Coating Types

Protective Coatings: These coatings protect the mirror surface from environmental factors like moisture and dust, extending the mirror's lifespan.

Anti-Reflective Coatings: Designed to minimize reflection losses, these coatings improve the transmission efficiency of the mirror, particularly in high-precision optical systems.

High-Reflective Coatings: These coatings are optimized for specific wavelengths, ensuring maximum reflection and focusing efficiency in laser and other wavelength-sensitive applications.

Laser Systems: In laser applications, the precise focusing and collimation capabilities of OAP mirrors are crucial for maintaining beam quality and efficiency. They are frequently used in laser cutting, welding, and material processing, where precise beam control is essential.

Optical Instrumentation: OAP mirrors are integral to various optical instruments, including telescopes, microscopes, and imaging systems. Their ability to focus light without introducing aberrations enhances the performance of these instruments, enabling clearer and more accurate observations.

Industrial and Research Applications: In industrial settings and research laboratories, OAP mirrors are used in a variety of precision measurement and alignment tasks. Their versatility and high precision make them indispensable in fields ranging from semiconductor manufacturing to quantum optics.

Bena Optics' Off-Axis Parabolic Mirror represents a significant leap forward in optical engineering, offering unparalleled precision and flexibility in beam focusing and collimation. With a range of coating options tailored to meet diverse application needs, these mirrors ensure optimal performance across a wide spectrum of industries.

Name | Coating Option | Off-Angle Options | Surface Roughness | Alignment Through-Hole | Designed for Ultrafast Laser Pulses | Reflectivity Parameters |

Gold-coated OAPs | Bare Gold & Protected Gold | 15°, 30°, 45°, 60°, 90° | <50Å & <100Å | No | No | Ravg≥94% (700-800nm) |

Aluminum-coated OAPs | Protected Aluminum | 15°, 30°, 45°, 60°, 90° | <50Å & <100Å | No | No | Ravg≥85% (400-700nm) |

Enhanced Aluminum OAPs | Enhanced Aluminum | - | - | No | No | Ravg>89% (250-450nm) |

Silver-coated OAPs | Protected Silver | 90° | <100Å | No | No | Ravg≥98% (2000-12000nm) |

Laser Line OAPs | Laser Line Coating | 90° | <50Å | No | No | >99.5% Reflectivity at Nd:YAG wavelength |

Ultrafast-enhanced Silver OAPs | Ultrafast-enhanced Silver | 90° | <50Å | No | Yes | Rs>99% @600-1000nm (0°) |

OAPs with Alignment Holes | Enhanced Al/Protected Au/Protected Ag | 90° | <50Å | Yes | No | - |