Types

Metal reflective films (Al for UV/visible, Ag/Au for IR) with protective dielectric layers (SiO, MgF₂).

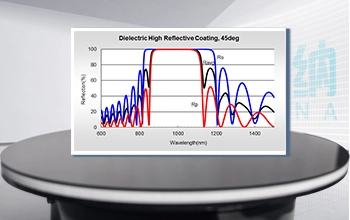

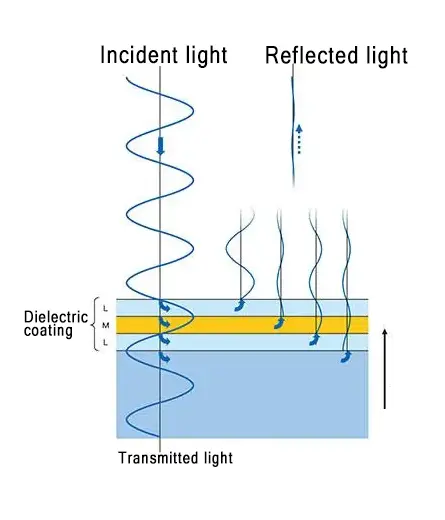

All-dielectric films using high/low refractive index stacks (λ/4 thickness).

Mechanisms

Metal films leverage high extinction coefficients to reflect ~90% light, while dielectric films rely on multilayer interference for >99% reflection.

Applications

Aluminum foil composites reflect 93% radiant heat for building insulation.

Laser optics use Au/Ag coatings for broad-angle reflectivity (e.g., CO₂ laser mirrors).

Limitations

Metal films suffer oxidation (requiring protective layers) and limited peak reflectivity (~90%)

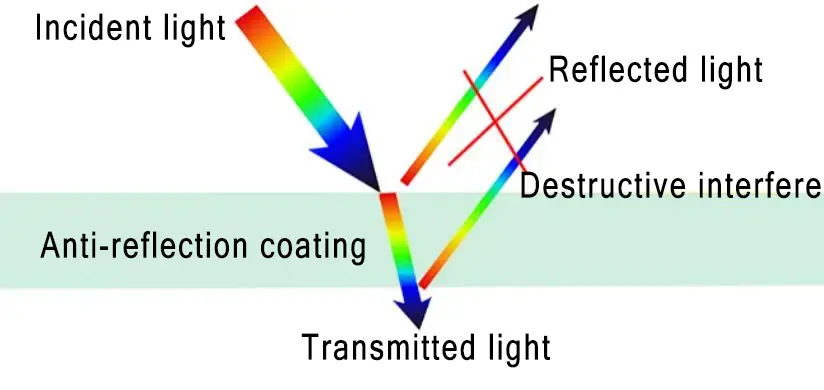

Principle: Reduces reflection via destructive interference between reflected light waves from coating interfaces

Design: Single-layer for narrowband (e.g., λ/4 thickness); multi-layer (e.g., double/triple) for broadband/low reflection

Materials: Modern crystalline silicon PV uses Si₃N₄ (high refractive index, PECVD-deposited); early PV used SiO₂/TiO₂

Applications: Optical lenses (e.g., reduced glare); solar cells (↑ light absorption, ↑ efficiency by ~4%)

Most optical materials can be coated, including common optical glass, Si, Sapphire, SiC, Ge, and more.

Yes, Bena Optics can meet various custom coating needs, including single-layer and multi-layer bandpass coatings.

Bena Optics uses physical vapor deposition (PVD) in a vacuum environment.

Bena Optics uses a Hitachi spectrophotometer for coating testing, covering a range of 180nm to 2900nm.

Yes, when extremely high reflectivity is required, metal plus dielectric coatings may be used based on product application needs.

Yes, we can accommodate large-size mirror coatings.