Optical quartz glass window plates, with advantages such as high temperature and pressure resistance, are irreplaceable compared to other optical materials. Quartz glass exhibits excellent ultraviolet transmittance and extremely low absorption of visible and near-infrared light, making it a fundamental material for optical fiber production. With minimal thermal expansion coefficient, high chemical stability, and bubbles, streaks, uniformity, and birefringence comparable to general optical glass, it is the preferred optical material for harsh environments. Main applications include: special light sources, optical instruments, optoelectronics, metallurgy, semiconductors, and optical communications.

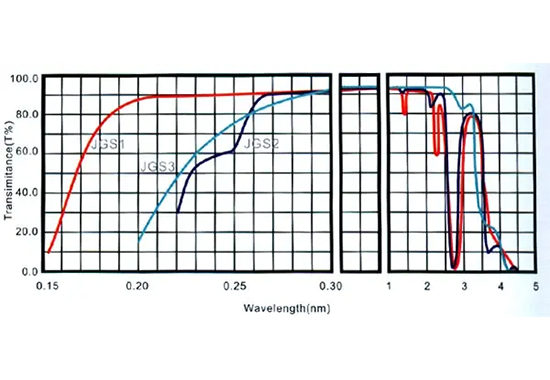

Produced by high-purity hydrogen-oxygen flame melting, this optical quartz glass contains a high hydroxyl content (2000 ppm) and offers outstanding ultraviolet transmittance, particularly in the short-wave UV range, far surpassing all other glasses. It achieves 90% transmittance at 185 nm and features a strong absorption peak at 2730 nm with no granular structure. It is an excellent optical material for the 185–2500 nm wavelength range.

Produced from quartz raw materials using a hydrogen-oxygen flame, this quartz glass contains trace metal impurities (tens of ppm). It exhibits an absorption peak at 2730 nm (hydroxyl content: 100–200 ppm) and contains streaks and granular structures. It is suitable for applications in the 220–2500 nm wavelength range.

Produced from quartz raw materials via vacuum electric melting, this quartz glass contains trace metal impurities (tens of ppm). It features minor bubbles, granular structures, and streaks, with almost no hydroxyl (OH) content. It demonstrates high infrared transmittance (over 85%) and is ideal for optical applications in the 260–3500 nm wavelength range.

| Material Property Specification Table | ||

| Category | Property | Standard Value |

| Mechanical Properties | Density | 2.2g/cm³ |

| Compressive Strength | 1100MPa | |

| Flexural Strength | 67MPa | |

| Tensile Strength | 48MPa | |

| Poisson's Ratio (μ) | 0.14-0.17 | |

| Young's Modulus (E) | 72000MPa | |

| Shear Modulus | 31000MPa | |

| Mohs Hardness | 5.5-6.5 | |

| Deformation Point | 1280℃ | |

| Softening Point | 1780℃ | |

| Annealing Point | 1250℃ | |

| Specific Heat (20-350℃) | 670J/kg·℃ | |

| Thermal Conductivity (20℃) | 1.4W/m·℃ | |

| Refractive Index | 1.4585 | |

| Thermal Expansion Coefficient | 5.5×10⁻⁷cm/cm·℃ | |

| Hot Working Temperature | 1750-2050℃ | |

| Short-Term Service Temperature | 1300℃ | |

| Long-Term Service Temperature | 1100℃ | |

Properties | JGS-1 | JGS-2 | HS |

Spectral Range (nm) | 180-2500 | 200-2500 | 260-3500 |

Average Transmittance | 90% | 85% | 85% |

Bubble Class | 0 | 2 | 2 |

Birefringence (nm/cm) | 1-2 | 1-2 | 1-2 |

Grain Structure Class | 1 | 2 | 2 |

Striae Class | 1-2 | 1-2 | 2 |

Homogeneity Class | 1-2 | 2 | 2 |

Fluorescence Class | 1 | 2 | 2 |