Aspheric components are widely used in high-end optical systems such as astronomical telescopes, smartphone cameras, laser systems, and advanced microscopes. Their complex curved surfaces enhance imaging quality but pose significant challenges for traditional testing methods. Computer-Generated Holography (CGH) has emerged as a critical solution by modulating laser wavefronts to accurately measure aspheric shape errors.

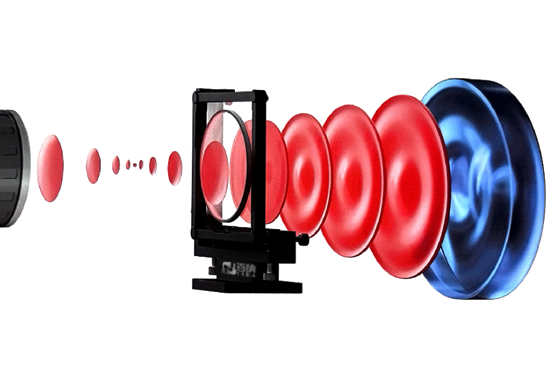

CGH uses computer algorithms to generate interference patterns that convert an incident spherical wavefront into a specific target wavefront (e.g., aspheric). During testing, laser light passes through the CGH, forming a matching wavefront that interacts with the aspheric component. The reflected wavefront interferes with the reference wavefront, producing a pattern that reveals shape deviations.

Bena Optics combines sub-micron precision machining with a customized Fizeau interferometer + CGH testing system to deliver flexible, efficient, and high-accuracy solutions:

High-Precision Testing: Sub-wavelength measurement accuracy for demanding optical applications.

Customizable Solutions: Supports multiple wavelengths and adjustable parameters to match diverse aspheric designs.

Fast Turnaround: 7-14 days for custom CGH production, accelerating R&D cycles.

Comprehensive Support: End-to-end services including installation, calibration, and technical assistance.