Laser lens materials are critical components in the manufacturing of laser optical elements. They must possess high laser damage thresholds, excellent optical transmittance, and appropriate thermal stability. Below are some common laser lens materials:

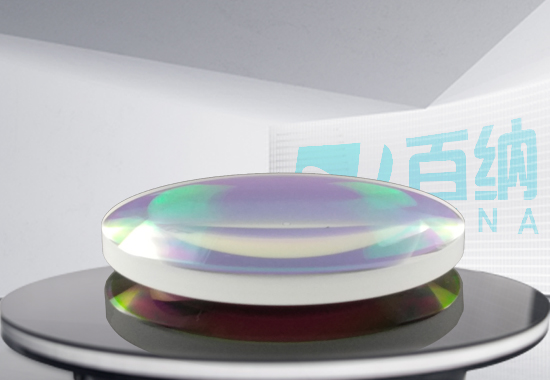

1. Optical Glass

Representative Materials: N-BK7 (Schott standard optical glass), K9 (Chinese standard optical glass)

Properties: High transmittance (350-2000 nm), good thermal and chemical stability.

Suitable Wavelength Range: Visible to near-infrared (VIS-NIR) laser applications.

Bena Optics Manufacturing Capabilities:

Precision Polishing: Advanced ring polishing and high-precision CNC polishing equipment ensure optical surface roughness (Ra) less than 0.1 nm.

Coating Technology: Provides various laser anti-reflection coatings (e.g., TiO2, SiO2 multilayer coatings) to enhance transmittance and laser damage resistance at specific wavelengths.

Customization: Can design aspheric or complex structured lenses based on customer requirements.

2. Fused Silica

Properties: High transmittance in the ultraviolet (UV) range (190-2500 nm), low thermal expansion coefficient.

Suitable Wavelength Range: UV lasers and high-power laser applications.

Bena Optics Manufacturing Capabilities:

Ultra-Precision Processing: Supports high-precision polishing and surface treatment for UV range, ensuring optimal UV transmittance.

Thermal Shock Resistance Design: Optimized thermal management for high-power laser applications to reduce thermal distortion.

3. Germanium (Ge)

Properties: High refractive index, suitable for the 2-16 μm near-infrared range.

Suitable Wavelength Range: Infrared lasers (e.g., CO2 lasers).

Bena Optics Manufacturing Capabilities:

Infrared Optical Processing: Specialized infrared polishing techniques ensure high transmittance and low absorption in the infrared range.

Custom Infrared Coatings: Provides anti-reflection coatings (AR Coating) to optimize performance in the infrared range.

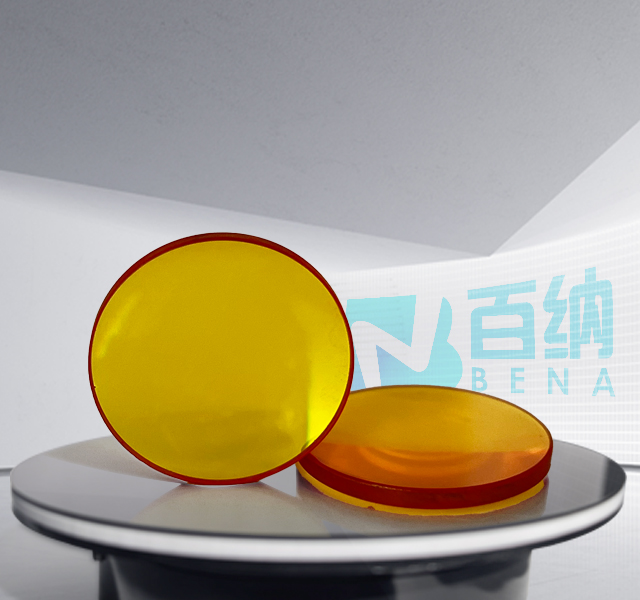

4. Zinc Selenide (ZnSe)

Properties: Excellent infrared transmittance (0.6-22 μm), suitable for high-power lasers.

Suitable Wavelength Range: CO2 lasers and other infrared laser applications.

Bena Optics Manufacturing Capabilities:

High-Precision Infrared Polishing: Advanced infrared optical processing to ensure high transmittance and low scattering for ZnSe lenses.

High-Temperature Coating: Provides laser-damage-resistant high-temperature coatings.

5. Calcium Fluoride (CaF2)

Properties: Extremely high UV transmittance (130-9000 nm), low refractive index.

Suitable Wavelength Range: UV lasers (e.g., excimer lasers).

Bena Optics Manufacturing Capabilities:

UV Precision Polishing: Supports high-precision UV optical processing, ensuring optimal performance for CaF2 lenses in the UV range.

UV Anti-Reflection Coatings: Provides UV-range anti-reflection coatings to reduce energy loss.

6. Silicon (Si)

Properties: Excellent infrared transmittance (1.2-8 μm), high laser damage threshold.

Suitable Wavelength Range: Specific infrared laser applications.

Bena Optics Manufacturing Capabilities:

Infrared Polishing Technology: Advanced infrared optical processing to ensure high transmittance and low scattering for Si lenses.

Infrared Damage-Resistant Coatings: Provides high-performance coatings resistant to infrared laser damage.

7. Laser Glass

Properties: High laser damage threshold, good thermal stability, and optical properties.

Suitable Wavelength Range: High-power solid-state lasers.

Bena Optics Manufacturing Capabilities:

High-Power Laser Optimization: Optimized design for high-power laser applications, enhancing thermal distortion and laser damage resistance.

High-Damage-Threshold Coatings: Provides anti-reflection coatings with high laser damage thresholds.

8. Amorphous Silicon (a-Si)

Properties: High laser damage threshold, good optical transmittance.

Suitable Wavelength Range: High-power laser applications.

Bena Optics Manufacturing Capabilities:

High-Power Laser Processing: Supports precision polishing and surface treatment for high-power laser lenses.

Damage-Resistant Coatings: Provides anti-reflection coatings with high laser damage thresholds.

9. Sapphire (Al2O3)

Properties: High hardness, excellent optical properties, and laser damage resistance.

Suitable Wavelength Range: High-power laser applications.

Bena Optics Manufacturing Capabilities:

Ultra-Hard Material Processing: Supports ultra-precision polishing and surface treatment for sapphire lenses.

Laser Damage Resistance Design: Optimizes thermal management and damage resistance for high-power lasers.

10. Phosphate Glass

Properties: High laser damage threshold, good optical transmittance.

Suitable Wavelength Range: High-power laser applications.

Bena Optics Manufacturing Capabilities:

New Material Processing: Supports precision polishing and surface treatment for phosphate glass lenses.

High-Damage-Threshold Coatings: Provides high-performance coatings resistant to laser damage.

Core Strengths of Bena Optics

Multi-Material Processing: Supports precision machining of various laser lens materials, including glass, fused silica, germanium, zinc selenide, calcium fluoride, and more.

High-Precision Polishing Technology: Uses advanced ring polishing and high-precision CNC polishing equipment, ensuring lens surface roughness (Ra) less than 0.1 nm.

Custom Coating Services: Offers anti-reflection coatings (AR Coating) and high-damage-threshold coatings for various wavelength ranges.

High-Power Laser Optimization: Optimizes thermal management and laser damage resistance for high-power laser applications.

Quick Response and Delivery: Provides customized optical lens designs and rapid delivery to meet urgent customer needs.