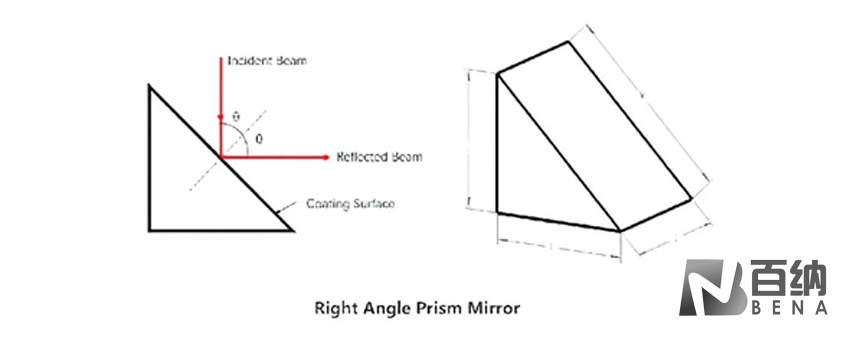

Right angle Mirror

Generally, anti-reflection coatings are applied to the right-angle edges, while reflective coatings are applied to the oblique edges. Right-angle prisms inherently have a large contact surface area and feature typical angles of 45° and 90°. Compared to ordinary mirrors, right-angle prisms are easier to install and exhibit better stability and strength against mechanical stress. They are the ideal choice for optical components in various devices and instruments.

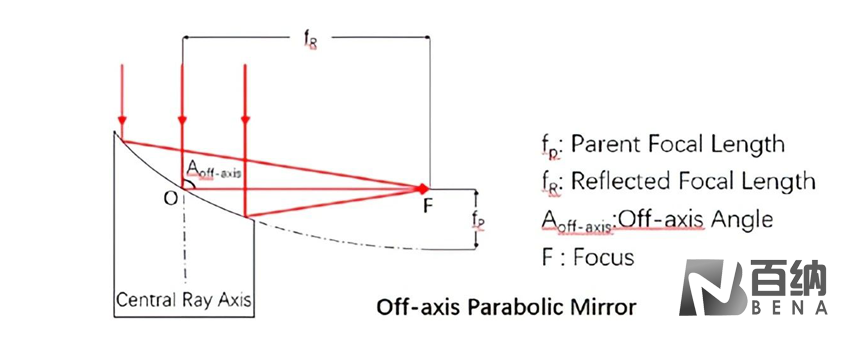

Off-axis parabolic Mirror

Off-Axis Parabolic Mirrors are surface mirrors whose reflective surface is a section taken from a parent paraboloid. These mirrors can focus parallel light beams or collimate point light sources, thanks to their off-axis design, which allows the focal point to be separated from the optical path. Unlike lenses, off-axis parabolic mirrors do not introduce spherical aberration or chromatic aberration, nor do they cause phase delay or absorption losses. This makes them highly suitable for femtosecond pulsed lasers.

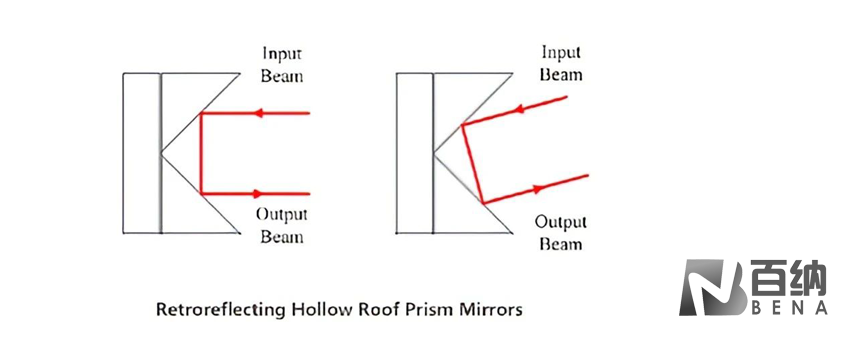

Hollow roof prism Mirror

The hollow roof prism mirror consists of two right-angle prisms and a rectangular base plate, all made of Borofloat material. Borofloat is known for its exceptionally high surface flatness and excellent optical properties, offering superior light transmission and minimal fluorescence across the entire spectral range. The oblique surfaces of the right-angle prisms are coated with silver films protected by a metallic layer, which provide high reflectivity in both the visible and near-infrared wavelengths. These two prisms are positioned with their oblique surfaces facing each other, and their dihedral angles form a 90 ± 10 arcsec. The hollow roof prism mirror can reflect light incident from the outside onto the prism's oblique edge. Unlike flat mirrors, the reflected light remains parallel to the incident light, thereby avoiding the influence of beam interference. This is more precise than manually adjusting two mirrors to achieve the same effect.