Bena Optics' Aspherical Lenses: Revolutionizing Optical Design

Aspherical lenses represent a significant leap forward in optical design, offering superior correction and performance compared to traditional spherical lenses. Bena Optics' aspherical lenses combine advanced manufacturing techniques with precision engineering to deliver exceptional optical solutions.

Design Considerations for Aspherical Lenses

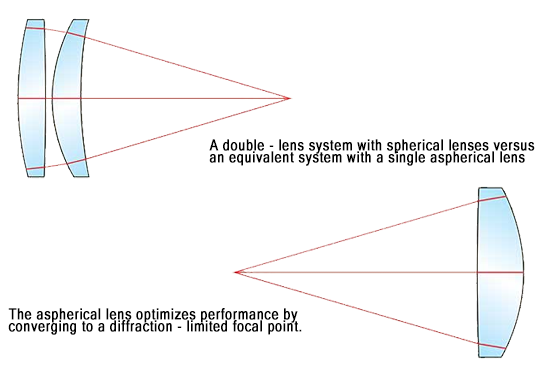

Aspherical surfaces are designed to correct optical aberrations inherent in traditional lenses, such as spherical aberration. These surfaces integrate multiple corrections into a single lens element, significantly enhancing optical performance.

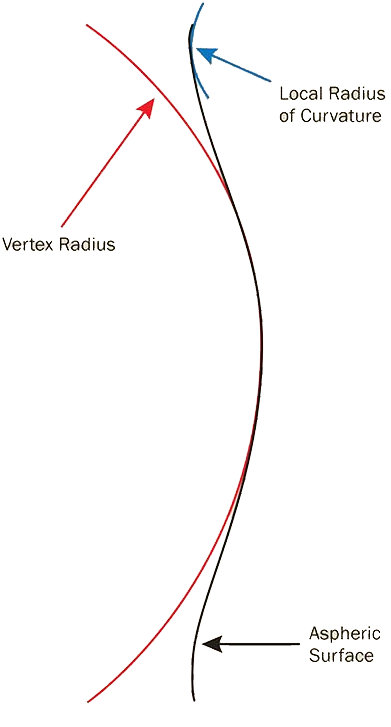

The local radius of curvature varies at different points on the aspherical surface, while the local radius of curvature at the center of the lens is defined as the vertex radius.

Manufacturability: Optical designers must understand the lens manufacturing process to avoid pitfalls such as complex shapes that are difficult to produce or test.

Cost and Lead Time: The cost and lead time of aspherical lenses depend heavily on manufacturing and testing technologies. By applying simple constraints during the design optimization process, designers can mitigate these factors.

Manufacturing Processes for Aspherical Lenses

The manufacturing of aspherical lenses differs from traditional spherical manufacturing due to the varying local radius of curvature on the surface. Bena Optics employs advanced techniques to achieve precise aspherical surfaces.

Manufacturing Method | Description | Advantages | Disadvantages |

Computer Numerically Controlled Grinding and Polishing | Grinding and Polishing with Subaperture Tools | Wide Material Selection; Large - Diameter Parts | Minimum Radius of Curvature; Difficult to Incorporate Mounting |

Magnetorheological Finishing Polishing | Variable - Viscosity Slurry | Wide Material Selection; Achieves Extremely Precise Surface Figures | Minimum Radius of Curvature; Requires Metrology Data; Can Induce Mid - Spatial Frequency Errors |

Diamond Turning | Point - like Tools Work Small Areas | Tight Radii Acceptable; Flexible Mounting Fab | Restricted Material Selection; High Spatial Frequency Errors |

Precision Glass Molding | Glass Heated and Pressed into a Mold Cavity | Low Per - Piece Costs for High Volume; Inflection Points and Tight Radii Acceptable | High Setup / Tooling Costs; Material Selection Restricted; Thickness Ratio Limited |

Plastic Injection Molding | Plastic Pushed into a Mold Cavity | Low Per - Piece Costs; Easy Incorporation of Mounting Features | High Setup / Tooling Costs; Material Selection Severely Restricted; Thickness Ratio Limited |

Applications of Bena Optics' Aspherical Lenses

Bena Optics' aspherical lenses are widely used in various applications where superior optical correction and performance are required, including:

Photography and Imaging: Enhances image quality by correcting spherical aberration.

Medical Optics: Used in diagnostic instruments for precise imaging.

Industrial Automation: Improves the accuracy of machine vision systems.

Bena Optics' aspherical lenses offer unparalleled optical performance, overcoming the limitations of traditional spherical optics. By leveraging advanced manufacturing techniques and precision engineering, Bena Optics provides exceptional optical solutions for a wide range of applications.

Visit our website to explore our full range of optical products and discover how we can help you achieve optimal performance in your optical systems.